Clutch Masters - 725 Series Twin Disc Steel Flywheel - TT Mk1 quattro

- Vendor Clutch Masters

- Part # FW-017-TDS

Secure Checkout

100% Secure SSL Encryption to Protect Your Info

Trusted Payment Options

We accept Visa, MasterCard, PayPal, Apple Pay & More

Hassle-Free 30-Day Returns

Return unopened items within 30 days for a refund or exchange.

Clutch Masters Flywheels are designed and tested to ensure the safety and quality of every flywheel. Years of R&D has given us the knowledge and firsthand experience to choose wisely the best material to manufacture flywheels that will surpass your expectations. Depending on the application, the majority of Clutch Masters flywheels are made from 1045 or 4140 Billet Steel. Clutch Masters Flywheels are SFI Certified meeting performance standards for the automotive and motorsport industry.

Benefits of a Clutch Masters Light Weight flywheel:

* Light-weight for improved performance and Quicker Rev’s.

* Reduces turbo “lag” in turbo-charged engines.

* Increased supercharger efficiency due to less drag on the crank.

* Improved mid-range torque in naturally aspirated engines.

* CNC Machined and balanced.

* SFI Certified.

Replacing your OEM flywheel with a lightweight flywheel may cause gear noise or a vibration that may not be suitable for everyone. The lighter the flywheel the more gear noise will be produced. Depending on the application Clutch Masters usually recommends Steel flywheels rather than Aluminum flywheels since Aluminum flywheels will cause more gear noise. Aluminum flywheels are usually only recommended for race applications looking to have the least amount of weight as possible. A lightweight flywheel may affect the life expectancy of a clutch kit depending on the application.

Going from a Dual-Mass Flywheel (DMF) to a Single-Mass Flywheel (SMF):

A Dual Mass Flywheel (DMF) is a flywheel in two concentric parts or two facing flywheels stuck together with flexible compound to damp down transmitted vibration and gear rattle for the gear box. Many newer model vehicles now come standard with a factory DMF. Many times enthusiast choose to replace a DMF with an SMF and here is why:

* DMF’s tend to be more expensive than an SMF.

* DMF’s are not designed to be resurfaced like conventional SMF.

* DMF’s usually weigh 30+ lbs depending on the application which will cause unwanted turbo lag.

* DMF’s cannot withstand a high rate of abuse and may fail under spirited driving.

Benefits of switching to a SMF:

* Reduced mass equals increased acceleration.

* Reduces turbo “lag” in turbo-charged engines.

* Increased supercharger efficiency due to less drag on the crank.

* Improved mid-range torque in naturally aspirated engines.

* SMF's are able to be resurfaced and can be reused.

Optional Flywheel Friction Lock:

Sometimes it takes a leap in technological advancement to solve those problems. One issue a lot of high powered cars can run into is the possibility of the flywheel coming loose. Flywheels can come loose for a variety of reasons, but once this happens you can pretty much kiss your crank goodbye. Typically if the flywheel comes loose it will end up welding (fretting) itself to the crankshaft and typically damages the crank beyond repair. This can end up being an incredibly costly problem.

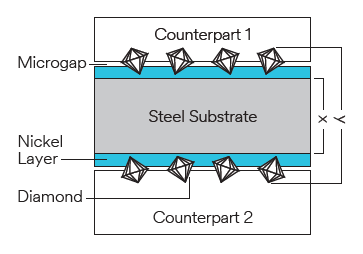

We've teamed up with global engineering powerhouse, 3M, to offer their friction shim technology specially developed for flywheel applications to provide that extra level of protection. Dubbed Flywheel Friction Locks, our FFLs consist of a nickel-coated steel substrate with partially embedded diamond particles. When placed between the flywheel and crank, the diamonds “bite” into each surface. With an installed thickness of .006"-.009" an FFL will not significantly alter assembly spacing. FFLs are easy to assemble and can be reused after disassembly.

Flywheel Friction Shim Cross Section:

To sum that up, by installing a Flywheel Friction Lock you give yourself a much better chance of the flywheel not coming loose in the first place, and if for some reason it does, you'll have an extra layer of very hard steel that can prevent the flywheel from damaging your crankshaft. It has been proven that our FFLs offer a simple and cost-effective way to reliably handle up to 5× higher shear forces and transmit up to 5× higher torque than conventional systems with no other modifications.